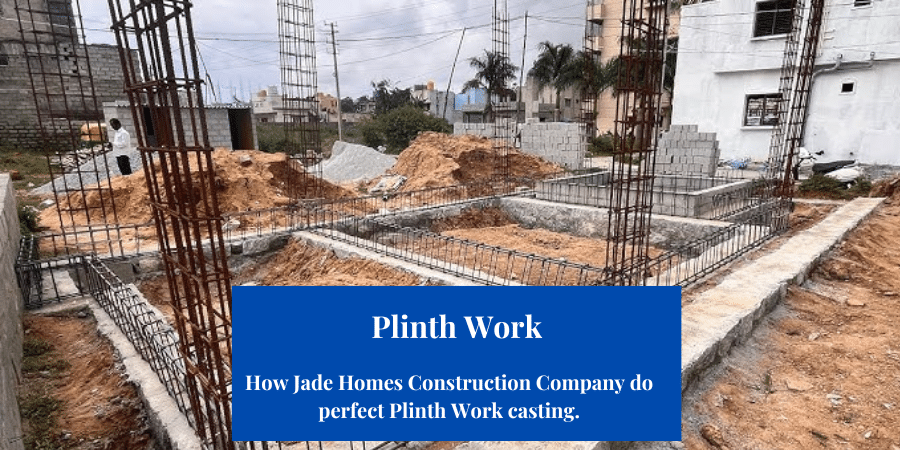

What is Plinth Work ? How Jade Homes Construction Company do perfect Plinth Work casting.

What is Plinth Work?

Plinth Work refers to the construction process that involves creating the base or foundation level of a structure above the ground. This level is critical for transferring the load of the building to the foundation and provides a stable base for the superstructure. It also serves as a protective layer against water seepage and ensures durability and stability.

Key components of plinth work include:

- Excavation and Leveling: Preparing the ground by excavation and leveling to ensure a stable base.

- Foundation Work: Constructing the foundation to support the plinth.

- Plinth Beam Casting: A reinforced concrete beam is cast at the plinth level to distribute the load evenly.

- Backfilling: Filling the area within the plinth beam with soil, sand, or other materials to create a level surface.

- Flooring Preparation: Preparing for the ground floor slab by compacting and layering materials as required.

How Jade Homes Construction Company Does Perfect Plinth Work Casting

Jade Homes Construction Company ensures the perfect execution of plinth work by following these best practices:

1. Thorough Planning and Design

- Detailed site analysis and soil testing to determine the foundation type.

- Creating precise designs for the plinth beam and foundation, ensuring compliance with structural requirements.

2. Quality Materials

- Use of high-grade cement, aggregates, and steel for reinforcement.

- Ensuring proper mix ratios for concrete to achieve the desired strength.

3. Accurate Excavation

- Excavating to the correct depth and width as per structural designs.

- Ensuring the excavation is free from loose soil or debris.

4. Precision in Plinth Beam Casting

- Proper placement of reinforcement bars (rebars) with accurate spacing and alignment.

- Using formwork that is sturdy and free of leaks.

- Ensuring even pouring and compaction of concrete using mechanical vibrators to eliminate air gaps.

5. Backfilling and Compaction

- Backfilling with selected material such as sand or soil in layers.

- Compacting each layer to achieve the required density and avoid settlement issues.

6. Waterproofing

- Applying a layer of waterproofing material on the plinth beam to prevent water ingress.

- Ensuring proper drainage systems to avoid water accumulation around the plinth.

7. Strict Quality Control

- Regular monitoring by engineers and supervisors at every stage.

- Conducting tests on materials and the finished plinth beam to verify strength and quality.

8. Timely Execution

- Following a well-defined timeline to ensure the project progresses efficiently without compromising quality.

By adhering to these meticulous steps, Jade Homes Construction Company delivers robust, durable, and high-quality plinth work that ensures the longevity and stability of the structures they build.

For More Detail Regarding Construction Consultation: